Call Us

+86-18368375685

Email Us

sales@zjhaili.cn

China Recycled Polyester Dope Dyed Pre-Oriented Yarn Factory

Our factory supplies GRS certified recycled polyester chips, recycled polyester yarns and recycled polyester flakes. We are recognized by the vast number of new and old customers for our high quality and perfect service.

Hot Products

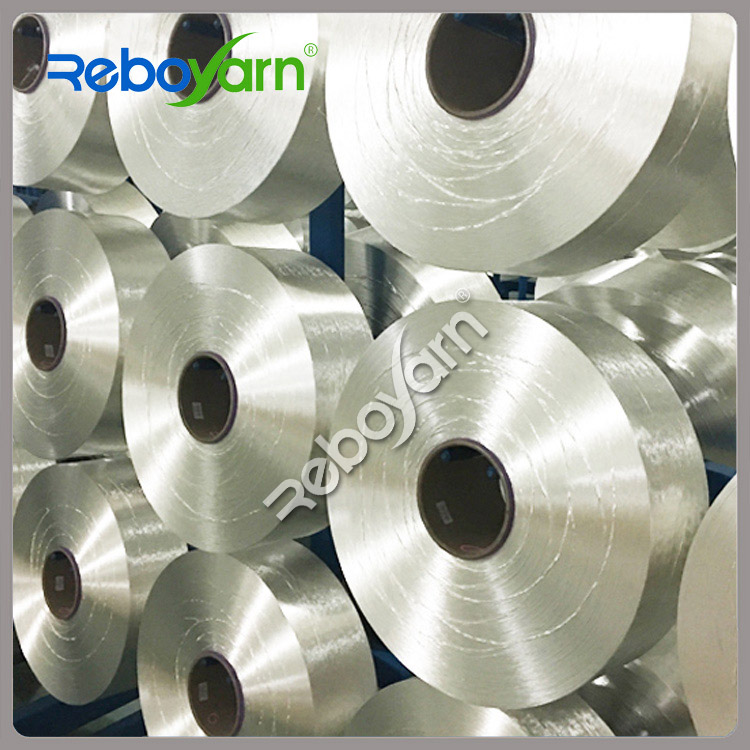

Recycled Polyester DTY Yarn Raw White Semi Dull

HAILI is a leading sustainable polyester solutions company in China. Our products made from post-consumer plastic bottles have good quality properties and are good for the environment and people. We cooperate with world famous brand companies to create sustainable textile industry.You can rest assured to buy Recycled Polyester DTY Yarn Raw White Semi Dull from our factory and we will offer you the best after-sale service and timely delivery.Dope Dyed rPET FDY With High Quality

HAILI is a professional manufacturer of recycled dope dyed yarn. We turn plastic bottles into high-fastness colored yarn by adding brand color masterbatch. For sure, the color can also be customized according to customer needs.You can rest assured to buy Dope Dyed rPET FDY With High Quality from our factory and we will offer you the best after-sale service and timely delivery.Recycled Polyester Chips Bright

HAILI's rPET chips meet the oeko-tex standard, which is good quality and good whiteness. Normal viscosity (0.73±0.01) is suitable for spinning and injection molding.As the professional manufacturer, we would like to provide you Recycled Polyester Chips Bright. And we will offer you the best after-sale service and timely delivery.Hot Washed Filament Grade PET Bottle Scraps Clear White

PET bottle flakes as high purity polyester raw materials are suitable for spinning and granulation. It is sustainable resources made from post-consumer plastic bottles. We supply bottle to bottle grade PET flakes as well.Welcome to buy Hot Washed Filament Grade PET Bottle Scraps Clear White from us. Every request from customers is being replied within 24 hours.GRS Certified Recycled Cationic Polyester DTY

Since the breakthrough in RPET cationic, HAILI has expanded the wider application of recycled polyester. Due to its particularity of dyeing performance, cationic series are widely used in weaving and kniting fabric for sofa, backpack, apparel, etc.As the professional manufacture, we would like to provide you GRS Certified Recycled Cationic Polyester DTY. And we will offer you the best after-sale service and timely delivery.GRS Certified Recycled Polyester Granule Semi Dull Filament Grade

As a professional wasted PET bottle recycler, HAILI has a complete rPET supply chain. We collect post-consumer plastic bottles and convert them into recycled chips filament grade suitable for spinning 300D to 1000D yarns and microfibers as well.As the professional manufacturer, we would like to provide you GRS Certified Recycled Polyester Granule Semi Dull Filament Grade. And we will offer you the best after-sale service and timely delivery.

Send Inquiry

X

We use cookies to offer you a better browsing experience, analyze site traffic and personalize content. By using this site, you agree to our use of cookies.

Privacy Policy